Sensors and limit switches are often overlooked components in the complex machinery of the oil and gas industry. They play a critical role in ensuring safe and efficient operations. These unassuming devices that monitor valve positions might be the one cog that prevents catastrophic failures. When limit switches falter due to poor mounting, the consequences can be severe, resulting in financial losses, environmental damage, and even safety hazards. Installing limit switches or sensors on quarter-turn valves like ball or butterfly valves is straightforward. However, challenges emerge when end-users require them for linear valves such as gate valves or globe valves.

The Perils of Poor Mounting

Traditional mounting methods for linear valves relying on flimsy brackets are inherently problematic. Exposed to the harsh conditions of oil and gas environments, these brackets are prone to:

- Vibration-Induced Failures: The constant vibration in pipelines and machinery can loosen brackets that can lead to inaccurate positional readings, false alarms, and equipment damage.

- Tampering: Inaccessible locations make limit switches and sensors vulnerable to tampering which is a serious security risk. Malicious actors can manipulate valve positions to divert or steal valuable products.

- Environmental Exposure: Limit switches and sensors are often exposed to extreme temperatures, humidity, and corrosive substances in the oil and gas industry. Poorly mounted components are more likely to succumb to these harsh conditions, leading to corrosion, short circuits, or complete failure of the device. This can result in undetected leaks, spills, or operational shutdowns, which will cause both environmental and financial repercussions.

- Difficulty in Maintenance: Poorly mounted limit switches and sensors are often harder to replace and recalibrate during routine inspections and maintenance. This not only increases the time and effort required to maintain the equipment but also raises the risk of human error during adjustments or repairs. In an industry where precision is critical, even minor mistakes can lead to significant safety incidents or production inefficiencies.

- Reduced Equipment Lifespan: Consistent exposure to adverse conditions due to poor mounting can degrade the integrity of limit switches and sensors over time. This not only increases the frequency of replacements but also adds to the overall operational costs. Additionally, repeated failures can lead to more frequent shutdowns, further compromising productivity and safety.

Case Studies

Case Study 1: A Costly Shutdown

Consider an oil refinery where poorly mounted limit switches led to an undetected valve malfunction. The misaligned switch failed to report the valve’s incorrect position, allowing a critical tank to overfill. The resulting spill caused extensive environmental damage, and the refinery had to be shut down for weeks to address the issue. The financial losses from halted production, cleanup efforts, and regulatory fines amounted to millions of dollars.

Case Study 2: Lost of Assets Due to Tampered Sensors

In a remote oil field, a petroleum company faced a perplexing issue—unexplained discrepancies between the recorded output and the actual amount of product reaching the processing facility. Despite no visible signs of leaks or equipment malfunction, the company was losing thousands of barrels of product annually. An investigation revealed that insiders exploited poorly mounted sensors on key valves to siphon off oil. The sensors, mounted on flimsy brackets, were easily tampered with, allowing the thieves to manipulate valve readings. They diverted product into hidden boats without triggering alarms through partial openings, and in small, incremental amounts to avoid drawing attention. Over several months, significant quantities of product have been siphoned, causing substantial financial losses. The theft was discovered after years of investigation and audits, leading to costly security upgrades and legal action against the culprits. This case highlights the importance of secure sensor mounting to prevent theft and ensure operational integrity.

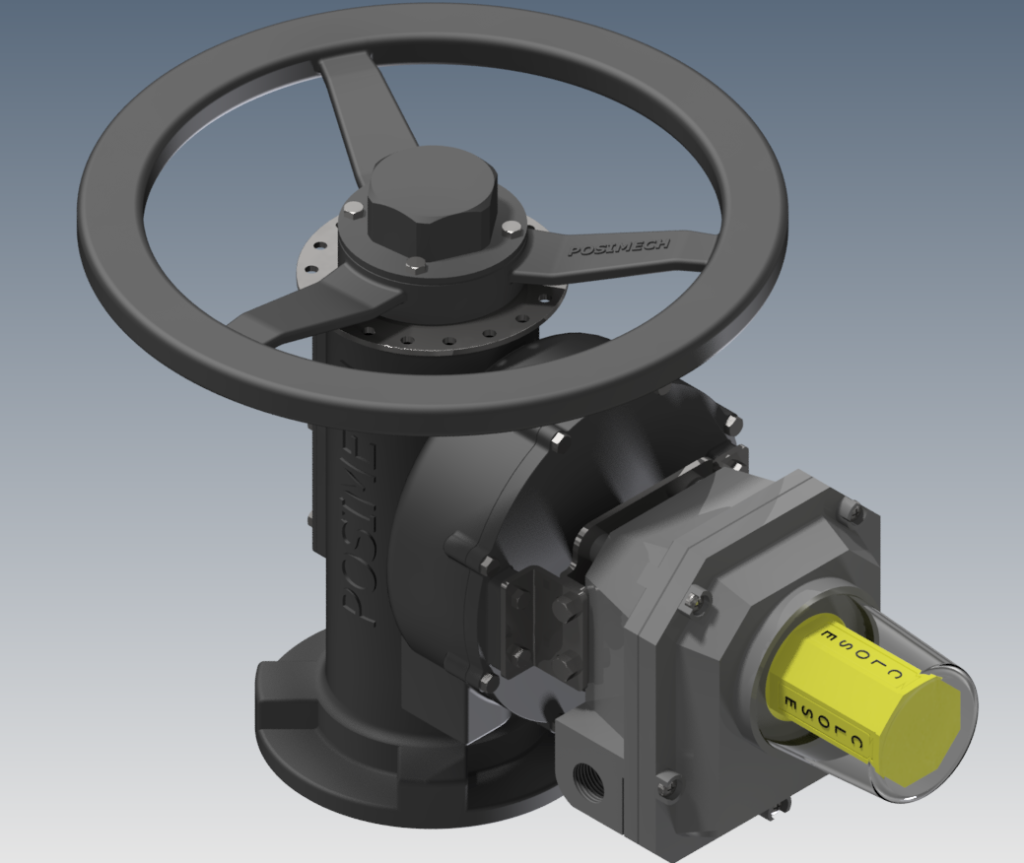

The Solution: PosiMech

The PosiMech is an innovative solution designed to provide peace of mind by ensuring reliable performance of limit switches and sensors, all encased within its robust structure. Engineered for universal compatibility, it supports a wide range of valves from different brands. Its lightweight construction, available in aluminum or stainless steel, allows for seamless integration with valves while delivering a clean and professional finish.

Conclusion: The Importance of Proper Mounting

Proper mounting of limit switches and sensors is a crucial aspect of maintaining safety, efficiency, and reliability in oil and gas operations. Investing in robust and well-designed mounting solutions can mitigate risks, prevent costly incidents, and extend the lifespan of critical equipment. Ensuring that limit switches are securely and accurately mounted is essential for avoiding the issues associated with poor mounting which would ultimately safeguard both the environment and the bottom line.

Discover how Trisome safeguards industry leaders’ assets and ensures the success of their process safety protocols with our product, the PosiMech HERE.