1. Gate Valves

Valves are fundamental components in various industries and play a crucial role in controlling the flow of fluids. With their diverse applications, understanding the different types of valves, their variations, and their specific purposes is essential for ensuring the efficiency, safety, and reliability of industrial processes. In this blog post, we’ll explore the most common types of valves and discuss their applications.

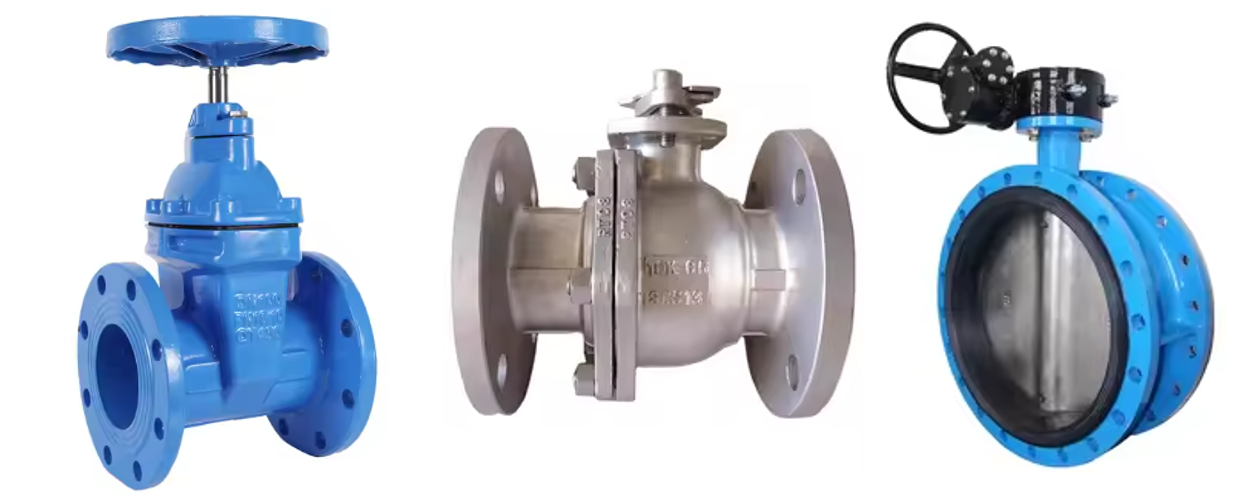

Purpose and Function: Gate valves are designed to start or stop the flow of a medium (gas or liquid) in a pipeline. They operate by raising or lowering a gate (or wedge) to open or close the flow path. These valves are ideal for applications requiring full flow or complete shutoff, as they offer minimal pressure drop when fully open.

Variations:

- Rising Stem Gate Valve: The stem of the valve rises as the gate is lifted, providing a visual indication of the valve’s position. It is commonly used where space is not a constraint.

- Non-Rising Stem Gate Valve: In this design, the stem does not rise; instead, it rotates to move the gate. This variant is suitable for installations with limited vertical space.

- Wedge Gate Valve: Features a wedge-shaped gate that provides a tight seal, making it ideal for applications involving liquids or gases.

Applications: Gate valves are widely used in a multitude of industries. They are particularly suited for services where the valve remains either fully open or fully closed for extended periods.

2. Globe Valves

Purpose and Function: Globe valves are designed to regulate flow in a pipeline. Unlike gate valves, they offer better throttling capabilities that allows for more precise control over flow rates. The valve’s disc or globe moves perpendicularly to the flow path to create a more significant pressure drop, which is better for flow regulation.

Variations:

- Tee Pattern Globe Valve: The most common design that offers high flow resistance and excellent throttling capabilities.

- Angle Globe Valve: Changes the flow direction by 90 degrees that reduces the number of fittings required in a piping system.

- Y-Pattern Globe Valve: Features a Y-shaped body that reduces flow resistance and pressure drop that makes it suitable for applications requiring both throttling and low pressure loss.

Applications: Globe valves are commonly used in systems where flow control is essential.

3. Ball Valves

Purpose and Function: Ball valves offer quick and reliable shutoff by using a spherical ball that rotates within the valve body to control flow. They are known for their durability and are excellent for applications requiring tight sealing and minimal leakage.

Variations:

- Floating Ball Valve: The ball is not fixed to the valve body that allows it to float and press against the downstream seat for a tight seal. It is commonly used in smaller piping systems.

- Trunnion Mounted Ball Valve: The ball is fixed at the top and bottom that provides support and reduces the operating torque. This design is suitable for high-pressure applications.

Applications: Ball valves are extensively used in industries where tight shutoff is critical, such as in oil and gas, petrochemical, and pharmaceutical industries.

4. Butterfly Valves

Purpose and Function: Butterfly valves are quarter-turn valves that use a disc to regulate flow. When the valve is fully open, the disc is rotated to be parallel to the flow direction, and when closed, the disc is perpendicular to the flow, creating a seal.

Variations:

- Wafer Butterfly Valve: A compact design that fits between two flanges that is suitable for applications where space is limited.

- Lug Butterfly Valve: Features threaded inserts (lugs) that allow the valve to be bolted to the pipe.

- Triple Offset Butterfly Valve: Provides a metal-to-metal seal that makes it suitable for high-temperature and high-pressure applications.

Applications: Butterfly valves are widely used in water treatment plants, HVAC systems, and in industries like chemical processing, food and beverage, and pharmaceuticals. They are favored for their lightweight, and cost-effectiveness.

5. Check Valves

Purpose and Function: Check valves, also known as non-return valves, allow fluid to flow in one direction only, preventing backflow. They are essential for protecting pumps and other equipment from damage caused by reverse flow.

Variations:

- Swing Check Valve: Features a disc that swings on a hinge or trunnion that is suitable for applications with a steady, moderate flow.

- Lift Check Valve: The disc lifts to allow flow and falls back to block reverse flow that makes it ideal for high-pressure systems.

Applications: Check valves are commonly used in water, steam, and gas systems, particularly where backflow prevention is crucial.

6. Diaphragm Valves

Purpose and Function: Diaphragm valves use a flexible diaphragm to regulate flow that makes them ideal for controlling the flow of corrosive or abrasive fluids. The diaphragm creates a tight seal to prevent leakage of hazardous materials.

Variations:

- Weir Type Diaphragm Valve: Features a weir or saddle on which the diaphragm closes. This provides good throttling capabilities.

- Straight-Through Diaphragm Valve: Offers a full bore that makes it suitable for slurries and viscous fluids.

Applications: Diaphragm valves are extensively used in the pharmaceutical, food and beverage, and chemical processing industries, where contamination-free operations and precise flow control are required.

7. Pressure Relief Valves

Purpose and Function: Pressure relief valves are safety devices designed to release excess pressure from a system, protecting equipment from overpressure conditions. They automatically open when the pressure exceeds a set limit and close once the pressure returns to safe levels.

Variations:

- Spring-Loaded Pressure Relief Valve: Uses a spring mechanism to control the valve opening, suitable for most industrial applications.

- Pilot-Operated Pressure Relief Valve: Utilizes a pilot valve to control the main valve, offering more precise pressure control.

Applications: Pressure relief valves are critical in industries where pressure build-up can be dangerous, such as in boilers, chemical processing plants, and oil refineries.

Conclusion

Valves are indispensable in managing the flow of fluids across various industries. Understanding the different types of valves, their specific variations, and applications helps industry professionals select the right valve for each application, ensuring optimal performance and safety. Whether it’s the precise control offered by globe valves, the quick shutoff of ball valves, or the backflow prevention of check valves, each type has its unique advantages tailored to specific operational needs. As industries continue to evolve, so too will the technologies and innovations surrounding these essential components, reinforcing their role in maintaining efficient and safe industrial processes.

Learn how Trisome empowers industry leaders with a sense of security and support their growth strategies by ensuring operational excellence here: https://trisome.com.sg/projects/